- Separation Membrane

- Dowel Bar Sleeve

- Peg Rod

- Sensor Wire

- Winch Stand

- Concrete Floater

- Backer Cord Roller

- Backer Cord & Debonding Strip

- Texturing Brush

- Expansion Joint Board

- Grove Cutting Blade

- Sealant Gun Nozze

- DWC Pipe

- Caution Tape

- Brown & Transparent Tape

- Sealant & Primer

- Crack Repair

- Ppe Fibre & Glass Fibre

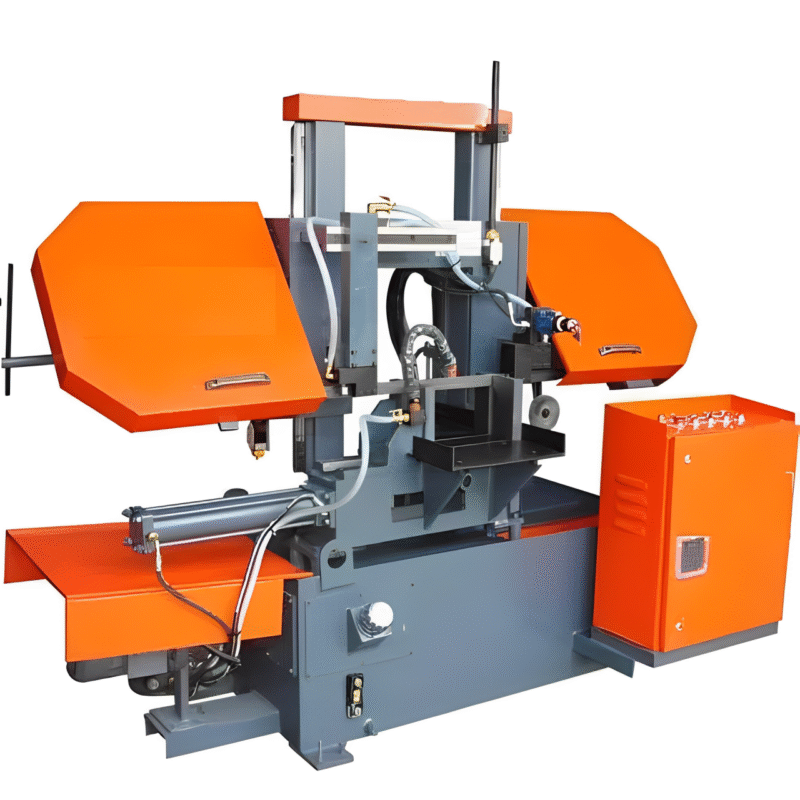

Dowel Bar Cutting Bandsaw Machine

Our Dowel Bar Cutting / Bandsaw Machine is a high-performance industrial-grade machine designed for precise and efficient cutting of dowel bars and similar metal rods.

Engineered for durability and accuracy, this machine is ideal for construction, road projects, and fabrication workshops where dowel bar preparation is essential.

Buy Bandsaw Machine Online Directly from Manufacturer

If you want to buy a bandsaw machine online, purchasing it directly from a reputable Bandsaw Machine manufacturer not only saves costs but also guarantees quality and reliability. As a good Bandsaw Machine supplier, we offer heavy-duty solutions that are designed to cut metal as well as wood, from small workshops to heavy-duty production houses.

By being customer-centric and precision-engineered machines, we have become one of the most sought-after names in the industry for customers who care about durability, performance, and fair prices. When you purchase a Bandsaw Machine online from us, you’re not really spending on equipment — you’re spending on long-term cutting precision and optimal functionality.

What is a Bandsaw Machine?

A band saw is a machine that uses a long tooth blade moving on a wheel to cut material supported by a table. It is one of the most frequent machine tools used in cutting shops and industries. A band saw’s primary use is to form irregularly shaped materials. The band saw cuts material by sawing it straight, round, or in a curve. Metal, wood, plastic, and other materials are cut with a band saw. Band saw blades vary depending on the material utilised. A bandsaw machine is powered by an electric motor. Many different types of band saw machines are used nowadays. Each performs a similar activity but has various properties for sawing material.

- Continuous Blade Design – In contrast to circular saws, bandsaws employ a loop-shaped blade, which enables more stable and consistent cutting.

- Uniform Cutting Speed – Bandsaws cut with uniform speed, minimizing wastage of material and making the cuts cleaner.

- Used Across Industries – Widely utilized in metalworking, woodworking, meat processing, and plastic production.

- Available in Various Sizes – Ranging from benchtop units to heavy-duty horizontal bandsaws.

- Can Cut Odd Shapes – Ideal for cutting curved, angled, and straight shapes.

- A Must for Production Lines – Increases productivity owing to speed, accuracy, and repeatability.

- Electric or Hydraulic Type – Depending upon the nature and magnitude of the operation.

Technical Features and Specifications of Our Bandsaws

Our Bandsaws are multipurpose power tools with a long, toothed metal blade that rotates in a continuous loop between two or more wheels. They are used to cut a variety of materials, including wood, metal, and plastic. Blade guards for safety, a table for material positioning, and wheels to move the blade are all essential characteristics. Modern bandsaws also have variable speed control, automatic blade tensioning, and specialised guides for precise cutting. Precision, efficiency, and safety are the key areas of focus of a committed Bandsaw Machine manufacturer like us.

- Heavy-Duty Steel Structure – Provides low vibration and stable cutting even during high workload.

- Adjustable Blade Tensioning – Adjustable according to the material type for greater precision and blade life.

- Sophisticated Hydraulic Systems – Our hydraulic systems provide smooth, automated feed and clamping action.

- Efficient Coolant Systems – Maintains blades cool during prolonged use, minimizing wear and tear.

- Variable Cutting Speeds – Provides flexibility for cutting metals, wood, or plastics.

- User-Friendly Control Panels – Easy interfaces for setting adjustments and observing performance.

- Safety Features – Emergency stop, blade guards, and overload protection are all included in every machine.

“Having advanced cutting features is essential, but safely operating heavy machines at the workplace is equally essential.

A Steel Wire Rope can most often be used to lift and position machines such as bandsaws safely, keeping the operator protected and extending the machines’ life.”

Advantages of Our Bandsaw Machines

Our Bandsaw machines have numerous benefits, including precision cutting, adaptability, and efficiency. They are noted for their ability to perform precise curved cuts, reduce material waste due to a narrow kerf, and work with a wide variety of materials. Bandsaws are generally regarded safer and easier to operate than certain other cutting instruments. As a reliable Bandsaw Machine supplier, we guarantee our machines provide functional, cost-saving benefits that increase productivity in various industries.

- Accurate Cutting – Less deviation makes for smooth, burr-free cuts even on difficult metals.

- Energy-Saving Design – Designed to use power most efficiently without any loss in performance.

- Less Operating Costs – Rugged construction translates to fewer breakdowns and reduced maintenance costs.

- Established Material Waste Reduction – Thin kerf blades result in minimal wastage on cutting.

- Versatility – Ideal for pipes, rods, angles, squares, sheets, and more.

- Minimal Downtime – Spare parts and services are easily accessible for rapid maintenance.

- Customisation Options – We have special models that are customized to individual production needs.

“Besides industrial material cutting using bandsaws, contractors also need a Groove Cutting Machine in concrete flooring. While the bandsaw provides accuracy in metals and plastics, the groove cutter provides accuracy when making joints and channels in concrete surfaces.”

Why Buy Bandsaw Machines from Our Manufacturing Unit?

Choosing the proper manufacturer of Bandsaw Machines is critical to ensure that your production runs smoothly and efficiently. Our manufacturing unit’s bandsaw machines are a fantastic choice due to its accuracy, versatility, and efficacy in cutting a wide range of materials. They are designed to be highly productive and long-lasting, with features like as robust construction, coolant options, and chip removal systems. Additionally, to maintain a safe working environment, our bandsaws are built with safety features such as blade guards and automatic shutoffs. Here’s why purchasing directly from us is the best choice:- Factory-Direct Pricing – Avoid middlemen. Prices are competitive, based on actual manufacturing costs.

- Quality Assurance – Each unit is strictly quality-checked before despatch.

- Technical Expertise – Years of engineering expertise enable us to offer customized solutions.

- On-Demand Spare Parts – Convenient availability of original spares and accessories.

- Quick Customer Support – A Special technical team to solve problems in time.

- Transparent Documentation – Receive comprehensive machine manuals, warranty details, and maintenance instructions.

- Quick Turnaround Time – Accelerated production and delivery due to in-house capacity and stock.

“To serve as an accessory to heavy-duty equipment like bandsaws, most construction and industrial facilities also use a Winch Stand for lifting and placing operations safely. This combination ensures smooth workflow with safety features maintained during handling equipment.

Best Bandsaw Machine Manufacturer in India

We have emerged as one of the most reliable Bandsaw Machine manufacturers in India, catering to customers from small fabrication plants to large-scale industrial units. Let’s go through the factors that make us the leading and top bandsaw machine manufacturer and bandsaw machine supplier in India:

- Decades of Industry Experience – Legacy of engineering excellence and reliability.

- Pan-India Distribution – Our machines are shipped and maintained across all major cities and industrial centres.

- ISO Certified Manufacturing – We stick to stringent quality, safety, and environmental regulations.

- In-House R&D Team – Endeavoring round-the-clock to improve machine efficiency and longevity.

- Strong Dealer Network – Our sales and support network makes quick assistance available wherever you are.

- Complete Line of Machines – From vertical bandsaws to automatic horizontal machines.

- Trusted by Industry Leaders – We’ve supplied well-known names in engineering, infrastructure, and manufacturing.

“In addition to reliable cutting equipment, many of our customers in fabrication and logistics also “We provide bandsaws to factories and industrial sites, and we are involved in “We provide bandsaws to factories and industrial sites, and we are involved in construction work that involves heavy jointing solutions. A Dowel Bar Sleeve is commonly used in road and pavement construction to provide concrete slabs with the capacity to bear weight and stay in line.”

What Makes Us a Reliable Bandsaw Machine Supplier?

Being in this industry for years, we have always believed in customer satisfaction and 100% authentic and good quality bandsaw machines online. Our quality, service, and long-term relationship commitment have enabled us to be the go-to Bandsaw Machine supplier online and offline.

- Ready-to-Ship Inventory – We stock best-selling models for immediate shipment.

- Nationwide Delivery – Logistics partners ensure we deliver the machines safely and quickly all over India.

- Professional Installation Support – On-site installation and demo by trained technicians.

- Online Buying Support – From consultation to checkout, our staff supports buyers at every stage.

- Live Video Demos – Order a virtual machine demo prior to purchasing the Bandsaw Machine online.

- After-Sales Service – Periodic maintenance and service packages guarantee continuous use.

- Customer Reviews & Trust – Hundreds of contented customers from various industrial segments

“Apart from reliable cutting machines, our fabrication and logistics customers also rely on consumables such as Brown & Transparent Tape to facilitate safe handling and packaging of completed products, ensuring a seamless process from production to dispatch.”

Frequently Asked Questions

Take into consideration the type of material, size, thickness, and frequency of cutting. We assist you in deciding according to workload and budget.

Consult the user manual tension chart. Our models are equipped with blade tension indicators to make it an easier process.

Wear protective equipment at all times, hold material securely, never cut corners, and avoid having your hands near the blade.

It is usage dependent, but usually after 6–12 months or when you see burn marks, excess vibration, or uneven cutting.

Yes, based on blade type and machine settings. Some designs are designed for cutting multiple materials.

Regular blade checks, cleaning coolant systems, motor health checks, and lubricating moving parts provide smooth operation.