- Separation Membrane

- Dowel Bar Sleeve

- Peg Rod

- Sensor Wire

- Winch Stand

- Concrete Floater

- Backer Cord Roller

- Backer Cord & Debonding Strip

- Texturing Brush

- Expansion Joint Board

- Grove Cutting Blade

- Sealant Gun Nozze

- DWC Pipe

- Caution Tape

- Brown & Transparent Tape

- Sealant & Primer

- Crack Repair

- Ppe Fibre & Glass Fibre

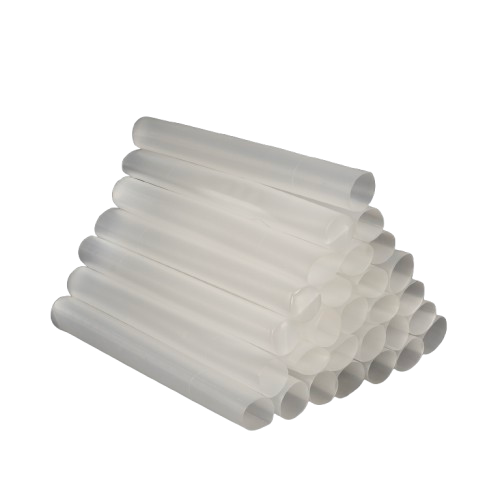

Dowel Bar Sleeve / Cap

Sleeves are used to prevent dowel bars from bonding with concrete, allowing the bars to slide within the sleeves when the concrete panels

expand and contract.

| Material HDPE | HDPE |

| Thickness | Upto 0.5mm thickness as per MORTH |

| Sizes (Suitable for bars) | 25/30/32/36/38/40mm |

| Length | 200/250/300/330/350mm |

| Colour | White (Pure virgin) |

Buy Dowel Bar Sleeve & Cap Online from Manufacturer

Want to purchase reliable and accurate dowel bar sleeves online and caps for your next infrastructure development project? Being a trustworthy manufacturer and seller, we provide best-quality dowel bar sleeves and caps online that provide secure load transfer and long-term joint performance in concrete pavements. We deliver the best-quality dowel bar online in standard size as well as custom size and follow tight industry standards and are dispatched pan-India.

Buying directly from a dowel bar sleeve manufacturer you can expect competitive prices, uniform quality, and technical support specific to your project requirements. Whether it’s road building, bridges, or industrial flooring, we are the best dowel bar sleeve supplier that supply essential reinforcement accessories you require to construct with confidence.

What is Dowel Bar Sleeve/Cap?

Dowel bar caps and sleeves are essential elements of concrete construction, applied mainly in jointed pavements to allow controlled movement with alignment between concrete slabs. The dowel bar participates in load transfer between two adjacent slabs, whereas the cap and sleeve possess protective and movement functions.

Dowel Bar Sleeve: Plastic or metal sleeve around the dowel bar end to enable movement and support contraction or expansion.

Dowel Bar Cap: Sleeve end cap that protects against entry of debris or concrete slurry into the sleeve, typically with contained compressible material to accommodate movement.

- These are packaged for field application in minimizing cracking, enhancing surface stability, and increasing pavement service life.

- The cap also serves as a safety and identification device during installation. Sleeves are generally installed on just one side of the joint only, with fixed and sliding ends.

- Dowel sleeves and caps are available in many various sizes, tolerances, and materials.

- They are commonly applied to highway, airport, warehouse, and border crossing construction.

Specifications of Dowel Bar Sleeve/Cap

Selecting the ideal dowel bar sleeve and cap online is based on the technical needs of your project. Being the leading dowel bar sleeve manufacturer and dowel bar sleeve supplier we offer the best specifications for your dowel bar. The following are general specifications we offer:

| Material | High-density polyethylene (HDPE), PVC, or galvanized steel (based on load and corrosion factors) |

| Length | 200 mm to 400 mm (based on bar diameter and project requirement) |

| Diameter Compatibility | Suited for dowel bar diameters of 25 / 30 / 32 / 36 / 38 / 40 mm only |

| Wall Thickness | 0.5 mm (as per MoRTH sleeves for durability and load resistance) |

| Cap Design | Compressible foam or spring inserts to allow axial movement |

| Colour Coding | Identification provided for some sleeves and caps |

| Standards | Produced as per IRC, ASTM, or BS standards (depending on project location) |

Dowel bar sleeves are used in joint construction to facilitate equal movement and distribution of loads; they are directly related to expansion joint boards, which also share the same purpose of controlling movement and stress in concrete. The interaction between these components keeps jointing systems usable and durable.

Key Features and Benefits of Dowel Bar Sleeve

Being the best dowel bar sleeve online and caps are made to optimize performance, enhanced joint stability, reduce friction and much more… let’s go through the key features and different benefits of buying from the top dowel bar sleeve manufacturer:

| Simplified Installation | Light in weight, easy to carry, and allows faster installation |

| Improved Load Transfer | Ensures maximum load transfer over joints without failure |

| Thermal Expansion Accommodation | Allows free movement of the slab under temperature variations without damage |

| Prevents Corrosion | Sleeves protect steel dowels from chemicals and water exposure |

| Durability | Built with long-lasting materials to withstand heavy traffic and harsh environments |

| Customisable | Available in various sizes and types to match different dowel bar specifications |

| Improved Structural Performance | Maintains slab alignment and reduces long-term maintenance |

Dowel bar sleeves serve to reduce joint failure, slab misalignment, and thermal expansion; they are connected directly to crack repair solutions procedures that address issues caused by inadequate load transfer or movement accommodation deficiency.

Why Choose Our Dowel Bar Sleeve?

With over decades of industry experience, we are the top dowel bar sleeve manufacturer and dowel bar sleeve supplier that are used by top contractors, the government, and infrastructure companies throughout India. Let’s go through the reasons of why you should choose our dowel bar sleeve:

- In-House Production: We manufacture everything within our factories to maintain consistent quality and better control over schedules.

- High-Quality Raw Materials: We manufacture our products using high-quality HDPE, PVC, or galvanized steel for more strength and durability in weathering.

- Stringent Quality Checks: Each batch goes through different stages of testing to ensure national and international specifications.

- Experienced Technical Staff: Our technical personnel can help with design, location, and size problems.

- Bulk Availability: High production capacity enables us to meet bulk orders for highways, airports, and metro lines.

- On-Time Delivery: Quick dispatch and logistics services are provided by us to assist your construction schedule.

- Competitive Pricing: Factory-direct prices are offered by us, which enable you to manage your project cost without ever compromising the quality.

Our range also includes high-performance sealant & primer, making us a one-stop solution for complete joint protection and durability in construction projects.

Best Dowel Bar Sleeve Manufacturer in India

We have emerged as India’s most reliable dowel bar sleeve manufacturer and dowel bar sleeve supplier by ensuring quality, innovation, and client satisfaction. Let’s go through the reasons that makes us the best dowel bar sleeve manufacturer in India:

- PAN India Presence: We deal with our products in major metro cities and rural areas with equal care.

- Experts in the Industry Trust Us: We’ve supplied material to metro developers, NHAI contractors, and leading infrastructure companies.

- Scaling up Production: We have high-volume production within our facility through automated lines and sophisticated moulding processes.

- Customisation Specialists: Do you have a special requirement or a non-standard size? We can provide custom solutions to suit your requirements.

- Third-Party Certification: Third-party certifications are available on request to meet project requirements as specified.

- Client-Centric Service: We don’t stop at sales—we deliver post-purchase services and support through feedback.

- Ongoing Innovation: We keep investing in R&D to enhance the strength of the product, cost savings, and installation ease.

It is referring to solid supply, having the material in stock, and recommending accessories. It is wise to associate with peg rod, another necessary accessory utilized for alignment and site preparation. The two products usually are sold together with infrastructure work.

What Makes Us a Reliable Dowel Bar Sleeve Supplier?

We are the top dowel bar sleeve manufacturers, end-to-end solution providers that promise each customer the right product at the right time according to their needs. Let’s go through the reasons that make us a reliable dowel bar sleeve supplier:

- Logistics Network: We provide door-step delivery services through our extensive network of logistic partners.

- Flexible Order Quantities: We help you with minimum 2000 units and up, we cater to all your order quantities with the same dedication.

- Stock Readiness: We maintain target sizes and types in stock to avoid project delays and interruptions.

- Technical Support: Our personnel help interpret technical plans and recommend suitable accessories based on conditions at site.

- Excellent Supplier Reputation: We have experienced long-term supply contracts with large government infrastructure agencies.

- Packaging & Labelling: Proper packaging and good labelling prevent confusion or damage during transportation or on-site handling.

- After-Sales Services: We are only a phone call away to rectify any problems after sale to provide hassle-free project implementation.

Dowel bar sleeves have significant uses in large projects such as highways, metro lines, and airports. Here, in this section, we are also discussing availability of DWC pipes in India, and using DWC Pipe also serves to refer to their application in infrastructure and government projects.

Frequently Asked Questions

They prevent debris as well as concrete from entering the sleeve, and the color-coded or extended design promotes visibility and reduces tripping hazards.

Sleeves are mainly manufactured from HDPE or PVC, though the caps can make use of compressible foams, plastic, or spring-loaded inserts for movement restraint.

They provide a barrier against air, chemicals, and water between steel that is enclosed and concrete, preventing the dowel bar from rusting and corroding.

Most dowel bar caps are one-time use. There are spring-loaded or foam caps removable and reusable according to site practice.

Yes, we produce dowel bar sleeves and caps in standard and custom sizes as per your project size and technical specifications.