- Separation Membrane

- Dowel Bar Sleeve

- Peg Rod

- Sensor Wire

- Winch Stand

- Concrete Floater

- Backer Cord Roller

- Backer Cord & Debonding Strip

- Texturing Brush

- Expansion Joint Board

- Grove Cutting Blade

- Sealant Gun Nozze

- DWC Pipe

- Caution Tape

- Brown & Transparent Tape

- Sealant & Primer

- Crack Repair

- Ppe Fibre & Glass Fibre

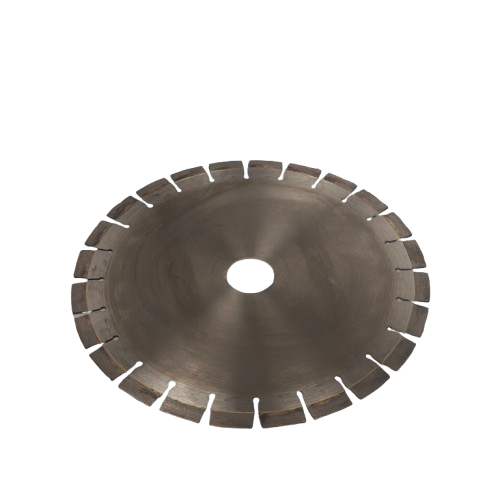

Diamond Groove Cutting Blade

Concrete Grove Cutting Blade is designed for precision cutting in a variety of applications, including concrete, reinforced concrete, natural stone, and cement. Crafted from high-quality mild steel and high-speed steel, this blade ensures durability and superior performance.

| Tool Type | Circular Concrete Grove Cutting Blade |

| Thickness | 3.5/4.2/6/7/10 mm |

| Sizes | 200mm to 1200mm |

| Bore hole | 50mm and 100mm |

Buy Concrete Groove Cutting Blade from Manufacturer

Need sturdy, high-precision concrete groove cutting blades? As a construction expert, contractor, or supplier, selecting an appropriate groove cutting blade can really impact performance, safety, and cost-effectiveness. At our manufacturing facility, we produce high-performance 14″ and 16″ diamond-tipped groove cutting blades designed for industry-grade concrete cutting.

Made to work in harsh Indian building conditions, our blades provide smooth, straight grooves with reduced wear and little vibration. From road building to flooring joints and expansion cuts, these blades provide consistent results project after project.

What is a Groove Cutting Blade and Where is it Used?

A groove cutting blade, also referred to as a concrete cutting blade, is a specialized tool designed for cutting clean and accurate grooves or joints in solid concrete surfaces. Groove cutting blades are usually diamond-segmented, enabling them to easily cut through reinforced or plain concrete.

Application in Road and Highway Construction – To create contraction joints and prevent random cracking.

Industrial Flooring Projects – Suitable for scoring control joints in factories, warehouses, and big commercial floors.

Pavement Repairs – Useful in repair work where grooving assists in material bonding or structural stability.

Expansion Joint Formation – Necessary in concrete slabs to facilitate controlled expansion and contraction.

Runway and Airport Projects – Applied in cutting long-wearing grooves with improved grip and drainage.

Bridge Decking and Structures – Critical in scoring concrete for drainage channels or structural reinforcement.

Drainage and Utility Channels – Proven effective in the creation of embedded utility channels in concrete for conduit or piping.

Specifications of Our Groove Cutting Blades

Our diamond groove cutting blades are designed to be highly efficient, accurate, and long-lasting in heavy-duty environments. Supplied in a variety of sizes and configurations to accommodate a broad scope of applications.

Blade Sizes: 14-inch and 16-inch diameters

Segment Height: 10mm, 12mm, and 15mm models available

Core Material: Heat-treated, high-tensile steel

Diamond Bond: Optimized for aggregate type and concrete hardness

Arbor Size: Standard 1″ but with optional custom options

Usage Type: Suitable for both wet and dry cutting use

Mounting Fit: Suitable for general groove cutting and concrete saw machines used in India

“Our Groove Cutting Blades are carefully designed for best-in-class operation, especially when used in combination with a Groove Cutting Machine. Such use ensures effortless cutting, longer blade life, and greater work efficiency when cutting concrete pavement or floor applications. Contractors prefer our blades in combination use with appropriate machines in order to achieve maximum accuracy, fast operations, and economical outputs at the site.”

Advantages of Using Our Concrete Cutting Blades in Construction

When reliability and performance are most critical, our groove cutting blades outshine. Here’s why construction experts in India rely on our products:

Higher Cutting Accuracy – Accurate and clean groove lines save post-processing and enhance joint appearance.

Increased Blade Life – Wear-resistant engineered diamond segments provide longer usage per blade.

Low Vibration and Noise – Saves machine strain and operator fatigue while ensuring stability.

Consistent Performance on All Grades of Concrete – Regardless of whether you’re cutting M20 or M40 concrete, our blades perform.

Minimal Chipping and Dust – Low-vibration operation equates to tidier work and better on-site hygiene.

High-Speed Cutting – Time-efficient for tight deadlines without sacrificing safety.

Reduced Power Consumption – Optimised segment shape enables quicker cuts with less strain on the machine.

Preferred by Contractors All Over India – Our blades are employed by highway contractors, builders, and civil engineering companies all over India.

“A careful cut with our Groove Cutting Blades makes it easy and professional to complete the finish with a Concrete Floater. Together, this ensures joints are properly formed and surfaces are even, level, and durable. Contractors throughout India prefer our blade in combination with concrete finishing tools for superior results which are longer-lasting and more efficient.”

Why Buy Our Concrete Cutting Blades?

All blades are not equal. Here’s why ours is the preferred choice for contractors, dealers, and infrastructure companies:

Made in India for Indian Conditions – Our blades undergo testing under local construction conditions.

High Quality Raw Materials – Hardened steel and high-quality diamond grit guarantee a better finish.

Stringent Quality Checks – Each blade is tested for performance, strength, and durability.

Competitive Price – We provide factory-direct prices to save you money on each purchase.

Custom Sizes Available – We provide customized setups according to your projec

To ensure optimum performance from our Concrete Cutting Blades, they should be used with a dependable Groove Cutting Machine. This combination offers maximum efficiency of cutting, enhances the longevity of the blade, and ensures exact joints are formed. Contractors from many parts of India have been using our blades, along with cutting machines, to achieve better speed, smoother results, and economy in the process. “”

Best Concrete Groove Cutting Blade Manufacturer in India

We take pride in being identified as one of India’s top makers of diamond groove cutting blades. Our design, production, and QA units within our premises guarantee each blade lives up to construction-grade standards. We comprehend the dynamics of the Indian market and provide products that excel on price vs. performance without compromise.

Years of Manufacturing Experience

High Production Capacity for On-Time Delivery

Blades Engineered Exclusively for Indian Road and Flooring Conditions

Pan-India Delivery Network

Partnerships with Renowned Infrastructure Companies

ISO-Certified Production Specifications

Outstanding After-Sales Support and Technical Service

“Using our Concrete Cutting Blades with a reliable Groove Cutting Machine ensures maximum performance. This combination offers maximum efficiency of cutting, enhances the longevity of the blade, and ensures precise joints are formed. Our clients across India have started using our blades with the cutting machines, and they are witnessing better speed, smoother results, and lower cost in the process.”

What Makes Us a Reliable Groove Cutting Blade Supplier?

Apart from production, we aim to be a reliable partner to our customers, ranging from small contracting companies to big infrastructure players.

Honest Business Practices – No extra costs, and comprehensive product specs revealed at the onset.

Regular Inventory Availability – Ship-ready inventory means you’ll never miss a deadline.

Flexible MOQs – We attend to small and big orders with the same commitment.

Quick Logistics – Our logistics personnel provide on-time and damage-free deliveries all over the country.

Custom Branding Option – OEM labelling available for dealers and resellers.

Customer Support Team – Timely support for product inquiries, choices, or after-delivery assistance.

Track Record of Client Satisfaction – High repeat order rate from long-term clients all over India.

“To help finish well after cutting grooves, many workers also use our Sealant Gun Nozzle with the blades. This makes sure sealant goes into the grooves accurately, reducing waste and improving joint performance. By using good-quality blades with dependable sealant tools, projects get lasting results with lower maintenance costs.”

Frequently Asked Questions

We provide standard 14″ and 16″ blades, with others on a custom basis by request.

Yes, our blades are designed for both wet and dry cutting, depending on the machine and conditions on the job site.

Clean the blade after every use, do not cut metal or abrasive debris, and store in a dry condition to avoid corrosion.

Yes, our blades are compatible with the majority of Indian standard concrete cutters and groove cutting machines.

Wear protective gear at all times, don’t force the blade, and allow the machine to do the work. Inspect the proper mounting prior to use.

We are able to tailor the diamond bond in accordance with whether you’re cutting soft, medium, or hard grades of concrete.

It varies with usage, but under regular conditions, our blades provide much longer life than those of common blades in the market.